What’s happening

Supply chain is the backbone of the manufacturing industry. A supply chain disruption is any event that causes a disruption in the production, sale, or distribution of products. It can include events such as natural disasters, regional conflicts, and pandemics. Disruptions have led to shortages of raw materials and components, which have forced manufacturers to cut production and raise prices. Shipping and manufacturing delays weren’t common, but COVID-19 left the world’s supply networks incapacitated, and several businesses fell apart. According to research by the Institute of Supply Chain Management, at least 75% of all surveyed businesses experienced disruption from the pandemic. As businesses are still recovering from manufacturing-related shortages from the pandemic, current geopolitical tensions are causing economic uncertainty and disrupting supply chains.

Despite the fact that the COVID-19 pandemic exacerbated supply chain shortages, the reality is that supply chain challenges are more complex than a single issue. While the current supply chain crisis is likely to be analyzed for years to come, several causes have already been identified, including a talent shortage, running close to capacity, a lack of diversified supply chain networks, increasing demand, the rise of protectionism, and geopolitical events.

According to the UN International Labour Organization, there were 255 million jobs lost globally as a result of the pandemic, with the global gross domestic product (GDP) falling by 4.4%. This figure includes both reduced working hours and job losses. By 2030, the Association of Manufacturers estimates that there will be a shortage of more than 2 million manufacturing workers in the US alone.

Running close to capacity refers to a situation where a business is operating at, or near, its maximum output level. This is a risky situation, as it leaves little room for error. If there is a disruption, such as a shortage of raw materials or a delay in shipping, it leads to production delays and shortages for customers. This is due to the increasing demand for goods and services and the lack of investment in capacity.

A lack of diversified supply chain networks can make businesses more vulnerable to disruptions when they rely on a single supplier or a small number of suppliers. A disruption at any one of those suppliers can have a ripple effect throughout the supply chain. This leads to shortages, delays, and higher costs. It can be more expensive to source goods and services from multiple suppliers.

The 2008 financial crisis resulted in a decrease in trade and investment, which led to calls for protectionism from businesses that had been affected by the decline in trade. Protectionism is the use of government policies to protect domestic industries from foreign competition. This can be done in a number of ways, including tariffs, quotas, and subsidies. Protectionism can have a variety of negative impacts. It can lead to higher prices for consumers, lower economic growth, job losses, and retaliation from other countries, which can further damage trade and investment. It is likely that the disruption will continue to be felt for some time as businesses and policymakers work to find solutions.

When shortages occur in one industry, the disruptions in that area nearly always spill over into adjacent companies and sectors. Global supply chain disruptions have had a significant impact on manufacturing. Some of the most notable impacts include increased costs, reduced output, longer production times, lower quality, and customer dissatisfaction. They do not just create higher prices and shortages among high-end consumer products, such as cars, but also lead to price inflation, factory closures, unloaded shipping containers, and negative effects on a nation’s economic wellbeing. They also affect a wide spectrum of products, from expensive goods such as cars and electronics to necessities such as food, medicines, oil, and gas, that have an impact on the cost of living.

In some cases, supply chain disruptions can have an even more direct impact than general disruptions, causing shortages of commodities the nation must have to ensure national security. This kind of disruption has the potential to jeopardize a nation’s very ability to defend itself and protect its population, in addition to issues of justice, equity, and general prosperity. Pharmaceuticals and personal protective equipment, energy, food, raw materials used in manufacturing, and semiconductors utilized in a variety of systems, including military applications, are just a few examples. Such shortages make the need for a national government to act more dire and immediate, thus raising the risk of conflict. In some cases, particular types of raw materials only exist in certain places, so shifting to more secure sources isn’t even possible. For instance, Taiwan currently dominates the market for semiconductors, giving it some negotiating leverage with other parties, such as the People’s Republic of China (PRC) on the mainland. As a result, Taiwan gains considerable negotiating power over the PRC and indeed the world.

President Biden’s administration has taken a number of steps to address this, including investing in infrastructure, reducing regulatory burdens, and working with allies by coordinating efforts to secure critical materials and by working to reduce tariffs and other trade barriers. The Department of Health and Human Services (HHS), under the Defense Production Act (DPA) and building on current public-private partnerships, will establish a public-private consortium for advanced manufacturing and onshoring of domestic essential medicine production. HHS will make an initial commitment of approximately $60 million from the DPA appropriation in the American Rescue Plan to develop novel platform technologies to increase domestic manufacturing capacity for Active Pharmaceutical Ingredients (API). The Department of Energy’s Loan Programs Office (LPO) will immediately leverage the approximately $17 billion in loan authority in the Advanced Technology Vehicles Manufacturing Loan Program (ATVM) to support the domestic battery supply chain. While this will help in the short-term, long-term solutions will take time to implement.

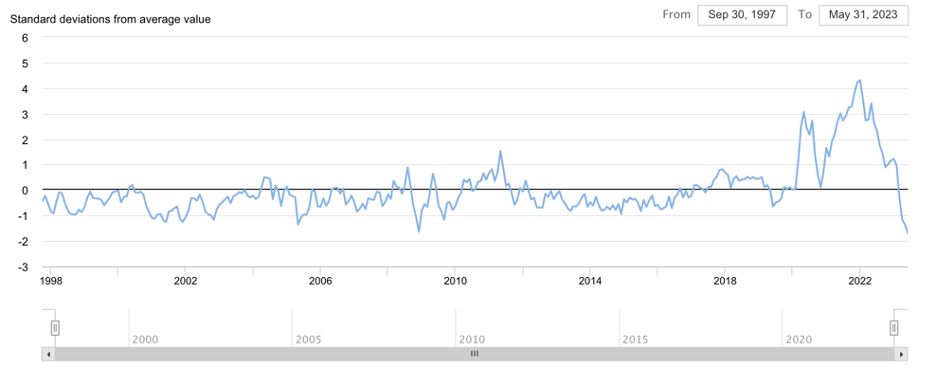

Global Supply Chain Pressure Index (GSCPI)

Resources :

- the impact of the supply chain crisis on the manufacturing industry https://www.randstad.com/workforce-insights/workforce-management/impact-supply-chain-crisis-manufacturing-industry/#:~:text=higher%20costs,higher%20material%20and%20operational%20costs.

- Supply Chain Disruptions: The Risks and Consequences https://www.rand.org/blog/2021/11/supply-chain-disruptions-the-risks-and-consequences.html

- Supply Chain Disruption – the Risk to Global Economic Recovery https://www.fticonsulting.com/insights/articles/supply-chain-disruption-risk-global-economic-recovery

- Biden-Harris Administration Announces Supply Chain Disruptions Task Force to Address Short-Term Supply Chain Discontinuities https://www.whitehouse.gov/briefing-room/statements-releases/2021/06/08/fact-sheet-biden-harris-administration-announces-supply-chain-disruptions-task-force-to-address-short-term-supply-chain-discontinuities/